MANAGEMENT SOFTWARE

FOR

REBAR SHOPS

Optimize every step of production.

Turn loss into profit.

375,000+

projects

Scheduled, produced and shipped

15,000,000+

tons of steel

Fully traced and delivered

225+

happy clients

Some saving £250,000/year with RebarExpert

ADVANTAGES

Drawing and Scheduling

Turning the plans for a project into a detailed steel list has never been easier.

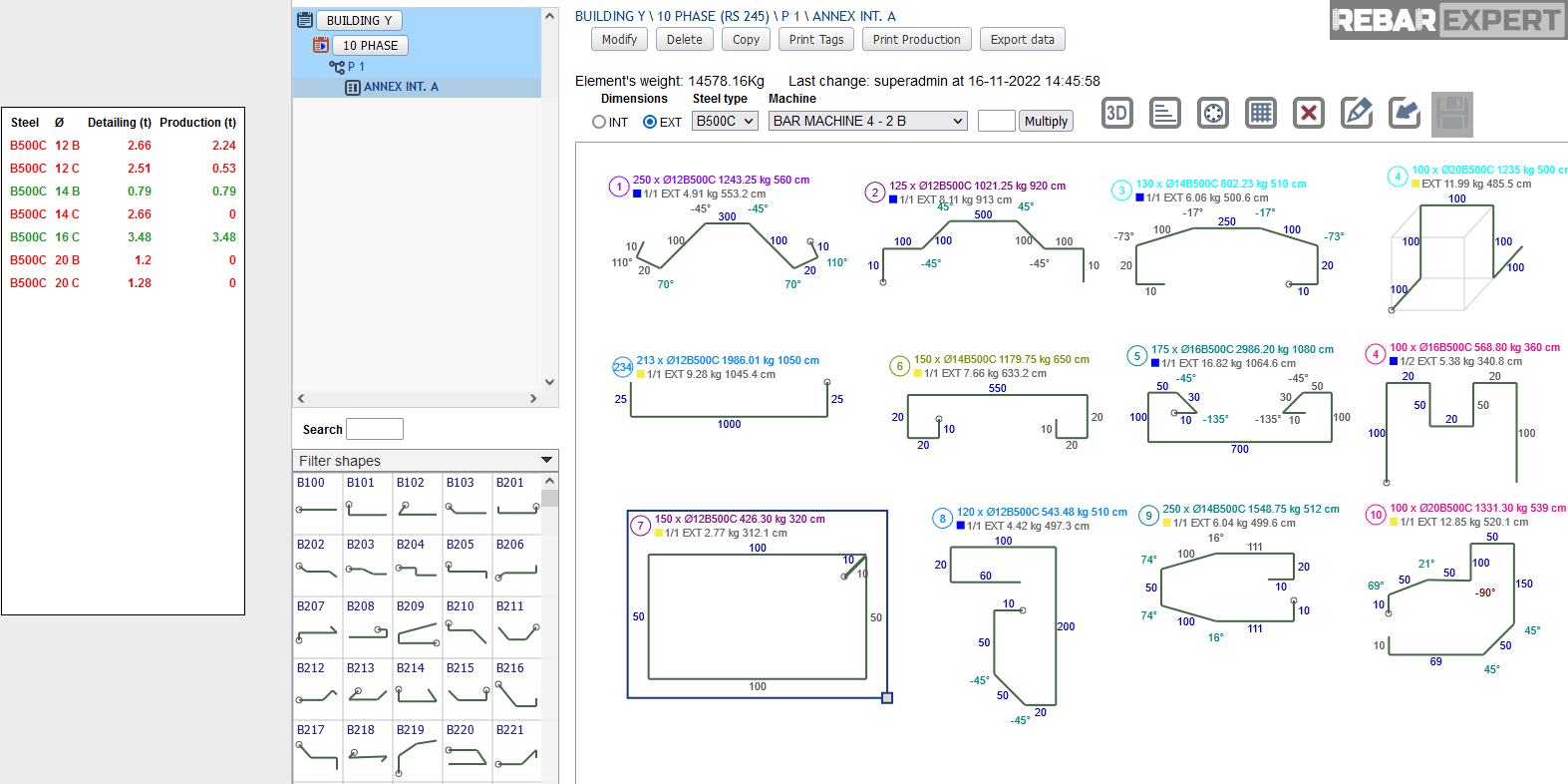

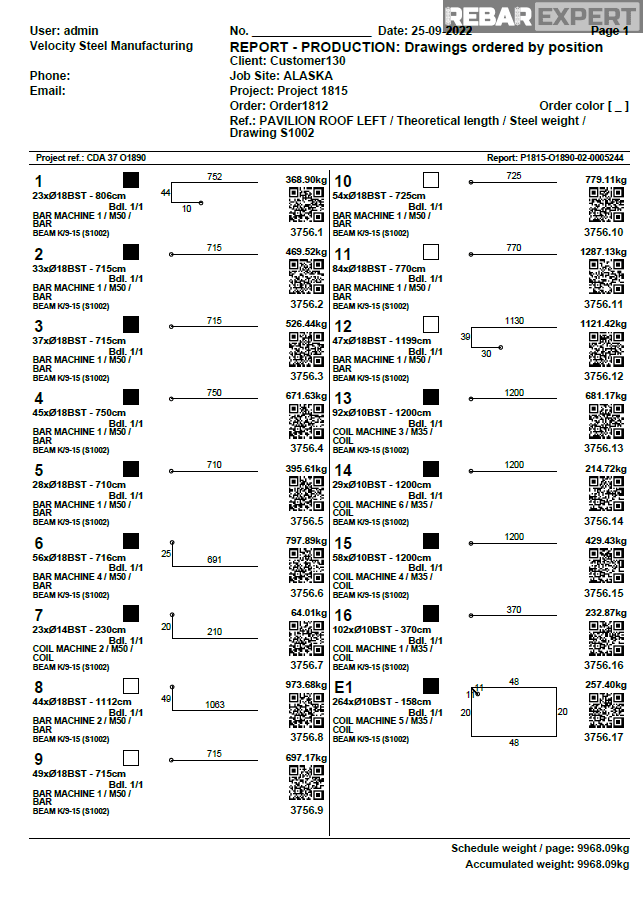

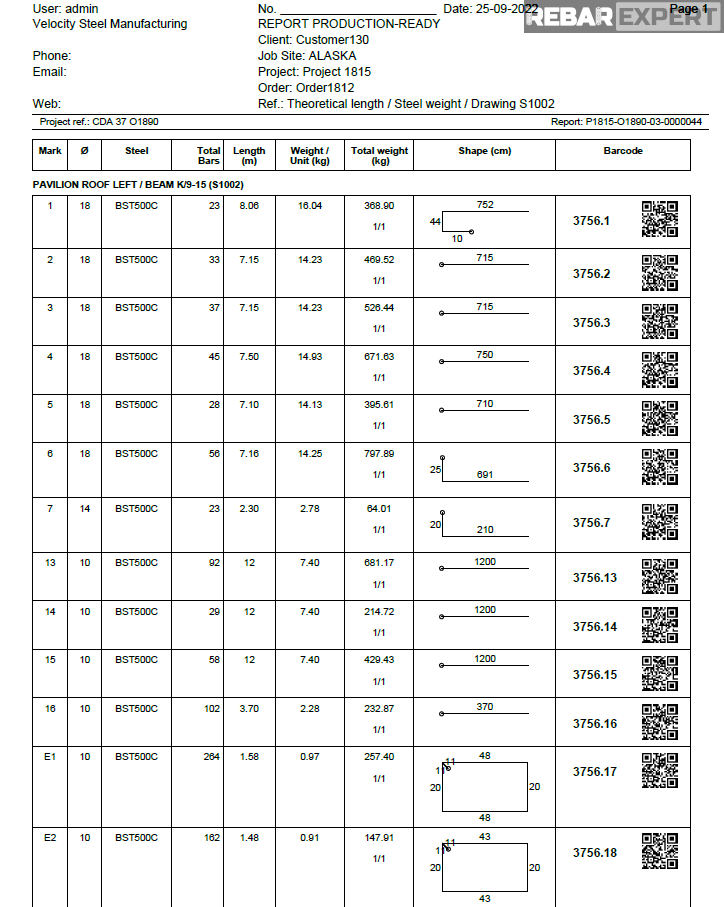

Faster and more accurate steel lists

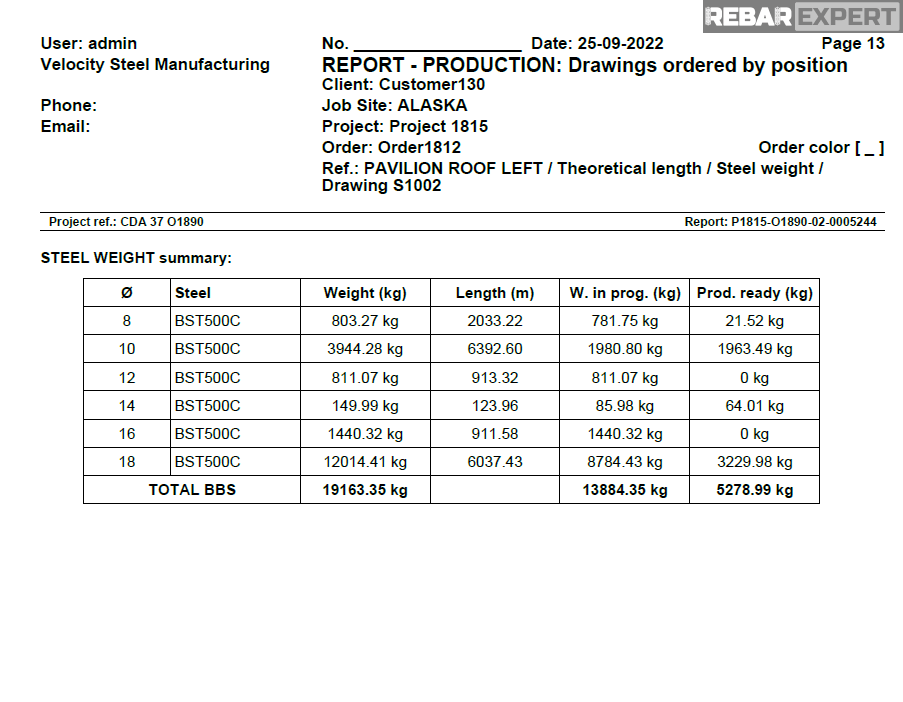

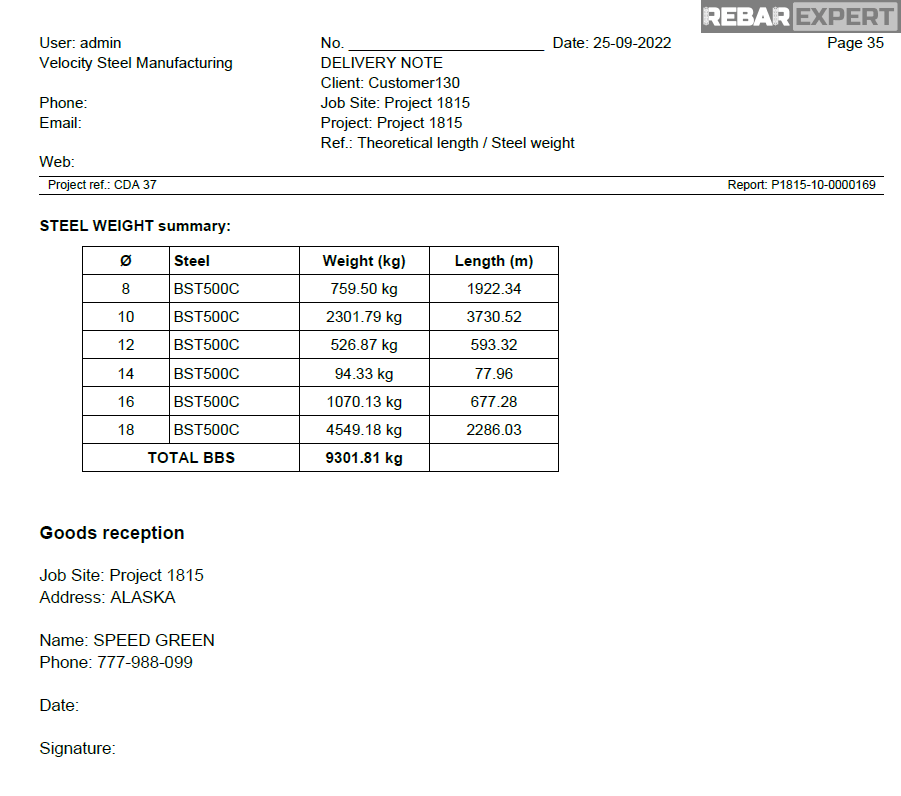

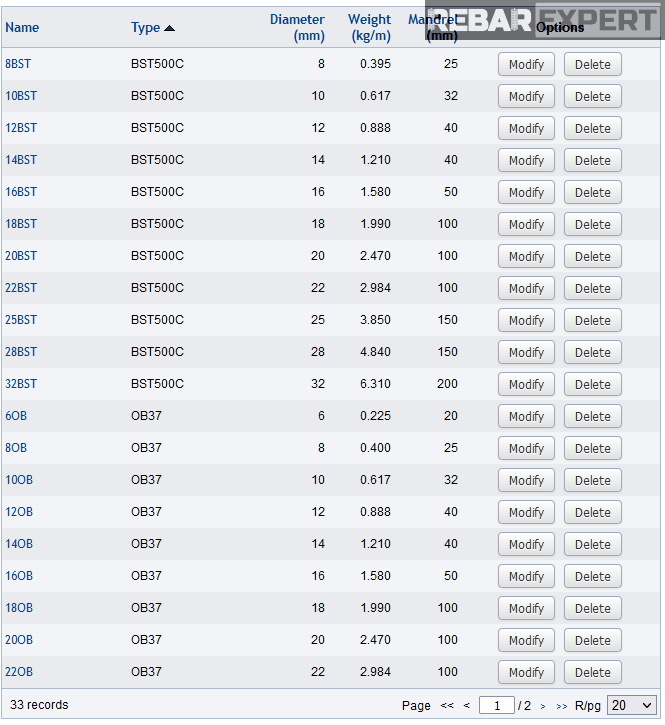

Time-saving features and built-in error-checking help you create error-free steel lists faster. The program calculates and provides weight totals broken down by steel grade, diameter (coil or bar), and status.

Automate all calculations with powerful formulas

Quantities, hook lengths, slope dimensions, and radius dimensions are automatically calculated and filled in for you.

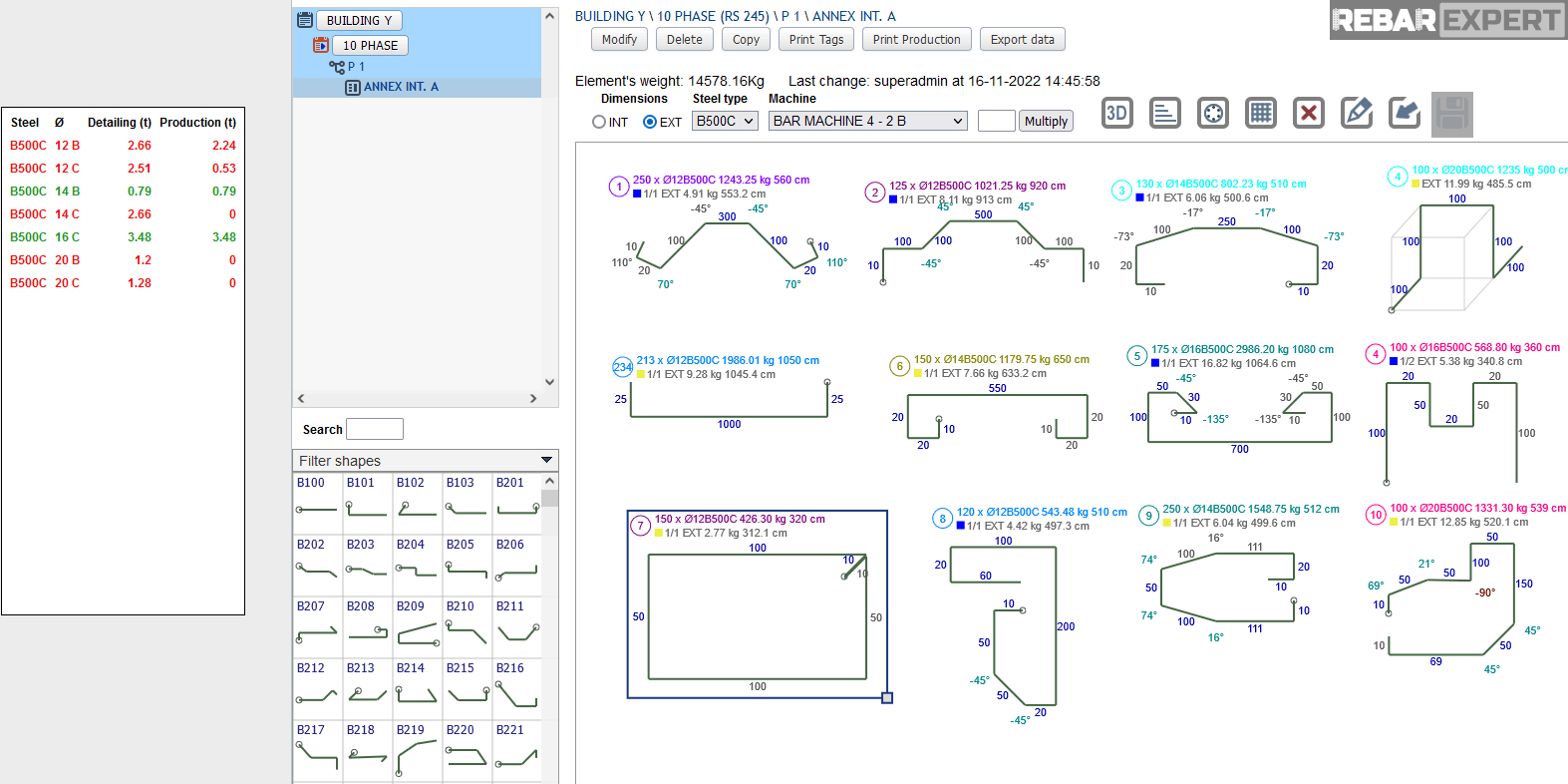

Eliminate hand-drawn tags

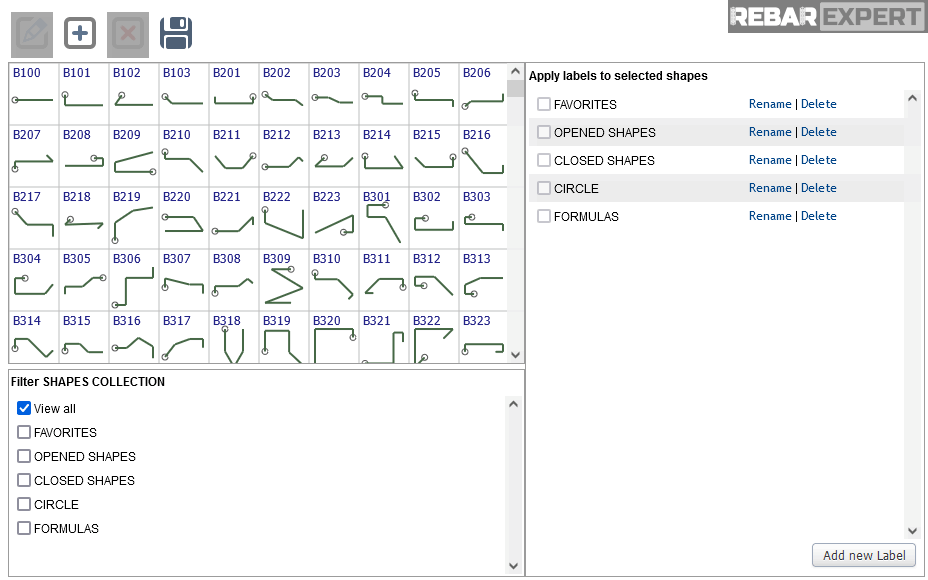

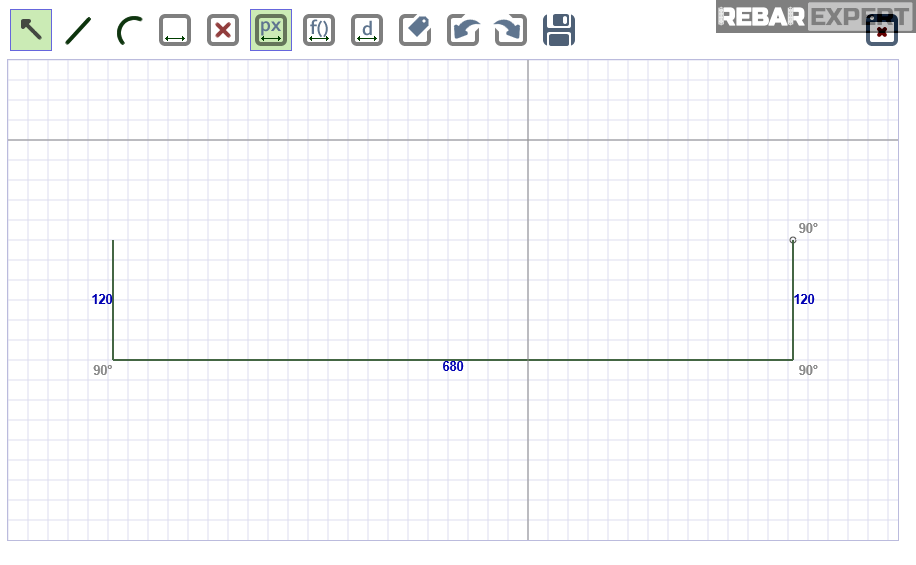

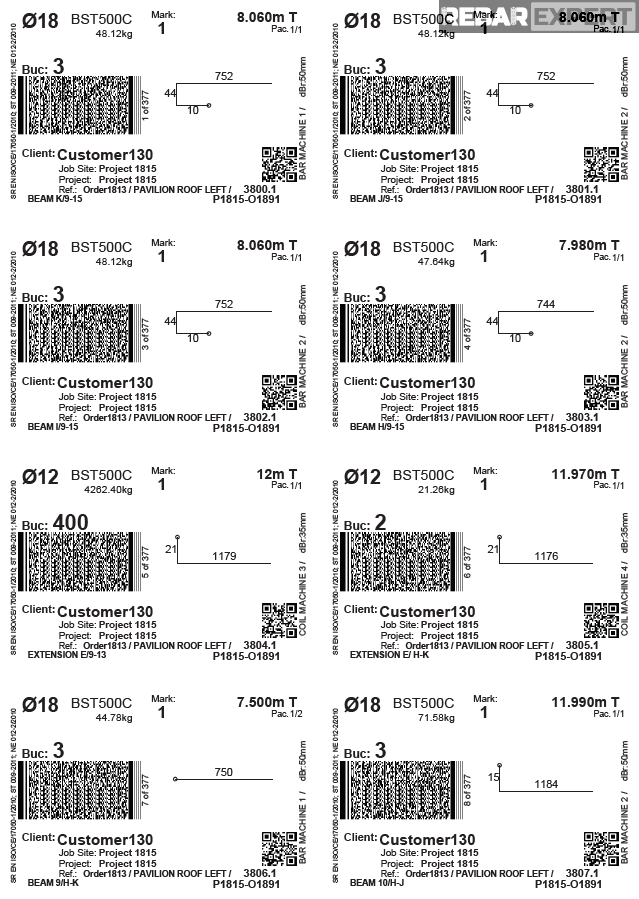

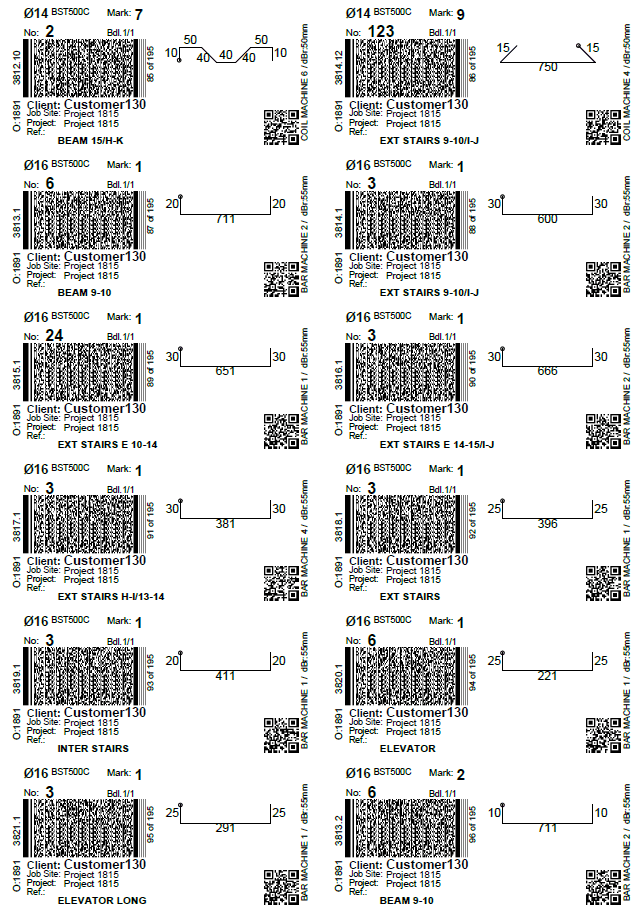

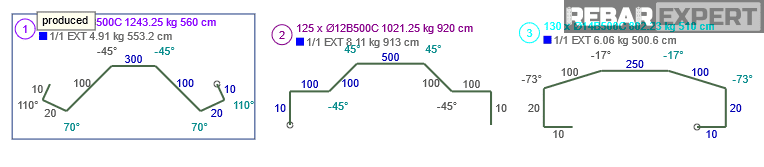

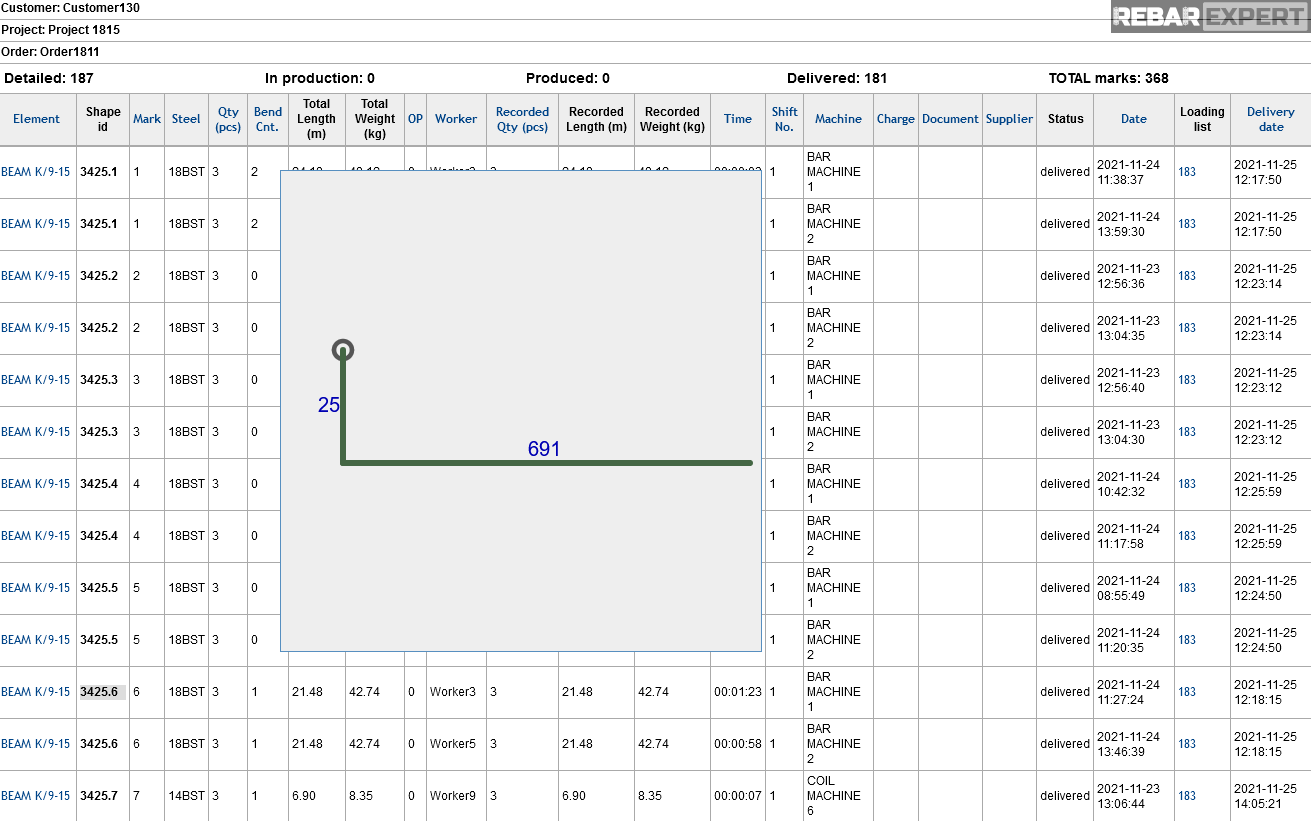

All industry standard shapes are built into the system, plus you can draw and define your own custom rebar shape designs. Rebar shape drawings automatically display on tags and reports.

No more scheduling with whiteboards and calculators

Do all of your scheduling with efficient digital tools.

Faster scheduling with multi-user access

Multiple engineers can work on the same project/order at the same time.

Easy editing without the need to enter the same information twice

Copy, Paste, Import, Export and Search tools are only a click away, making edits quick and simple.

Forget the piles of paperwork

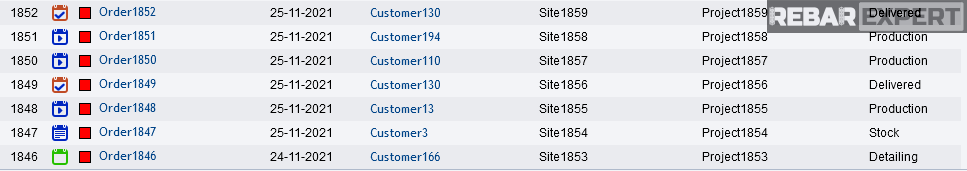

Scheduling tells you everything you need to know from macro (project, order) to micro (member, position)

No experience needed

No computer drafting experience or training in AutoCAD is required.

HOW IT WORKS

RebarExpert in Action

Get to see how RebarExpert integrates at every stage of the production flow from detailing and production to delivery, also covering validation and advanced reporting.

Detailing using proprietary CAD module with advanced features.

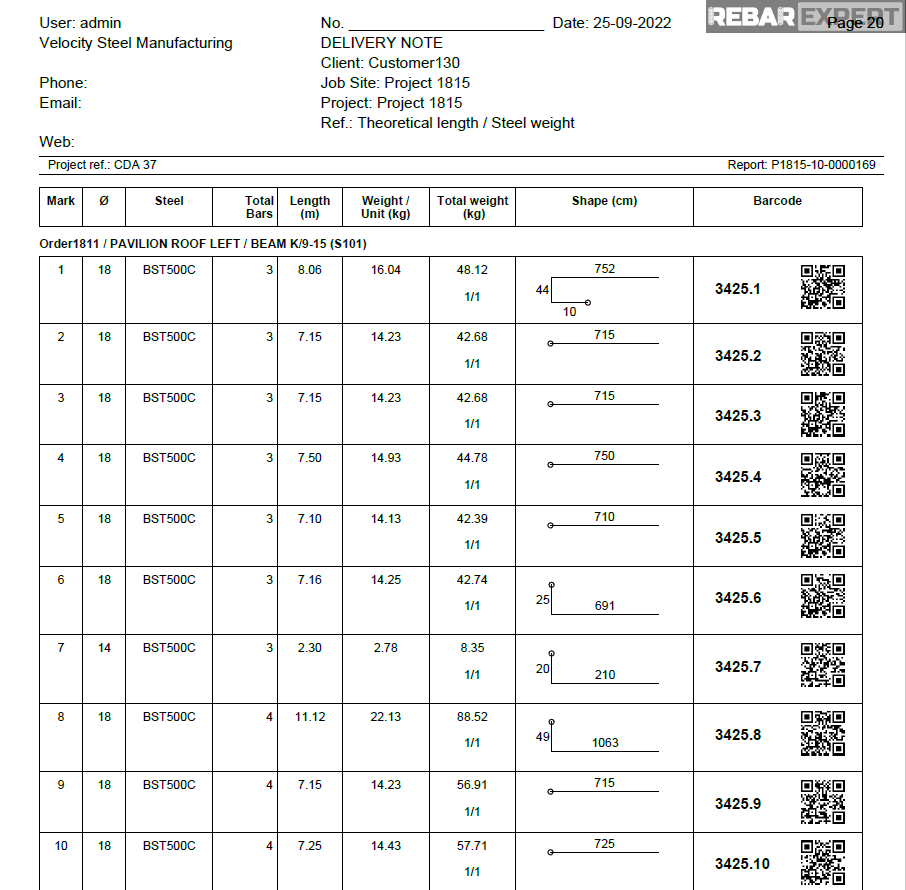

Generation of steel lists and machine readable tags.

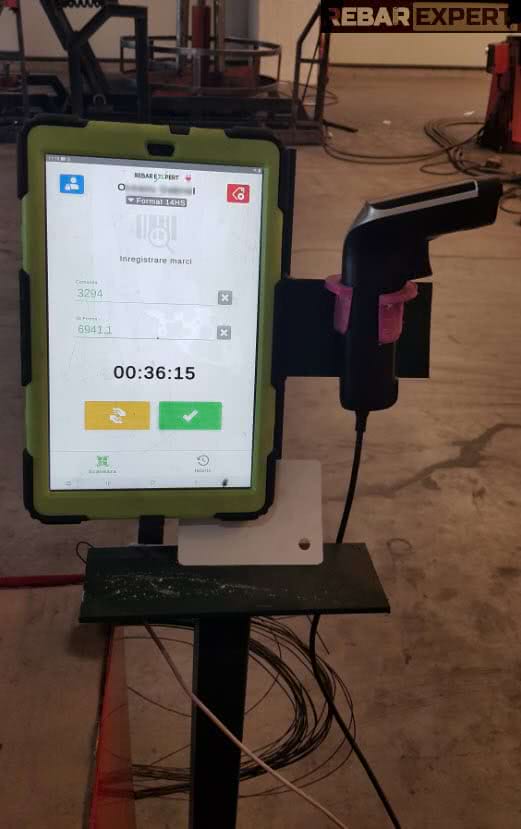

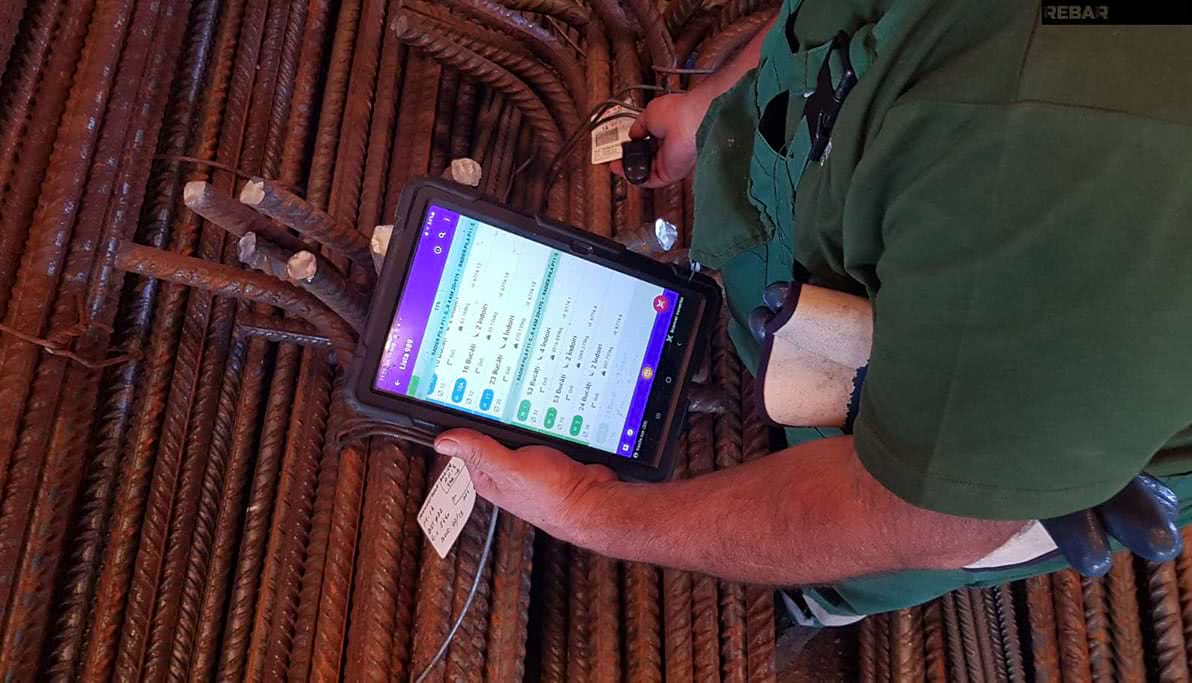

Working with BVBS-compliant tags and real-time production recording.

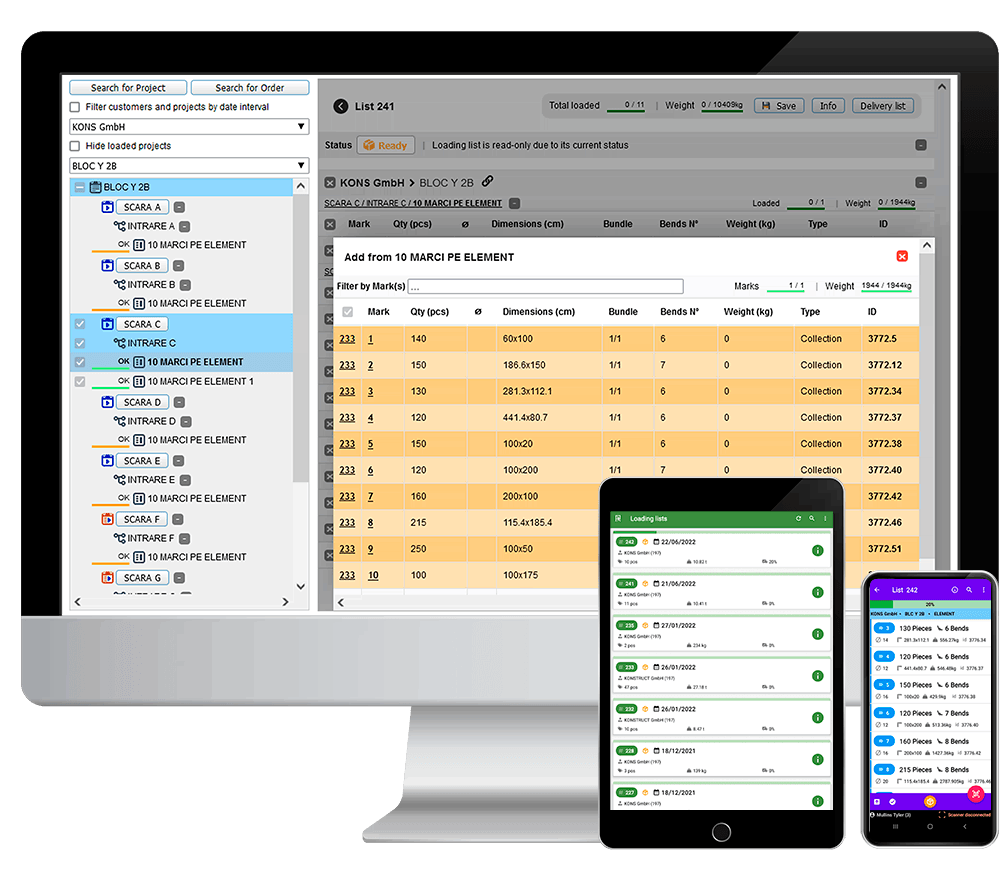

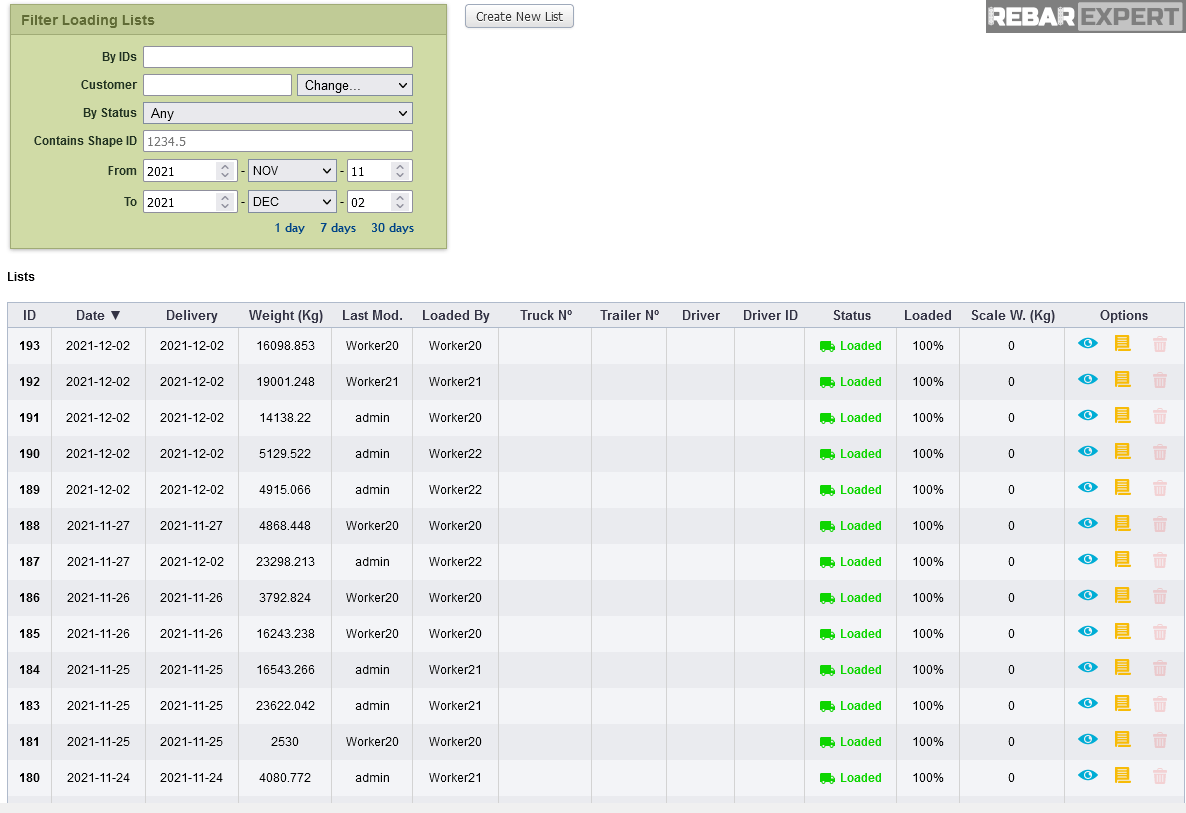

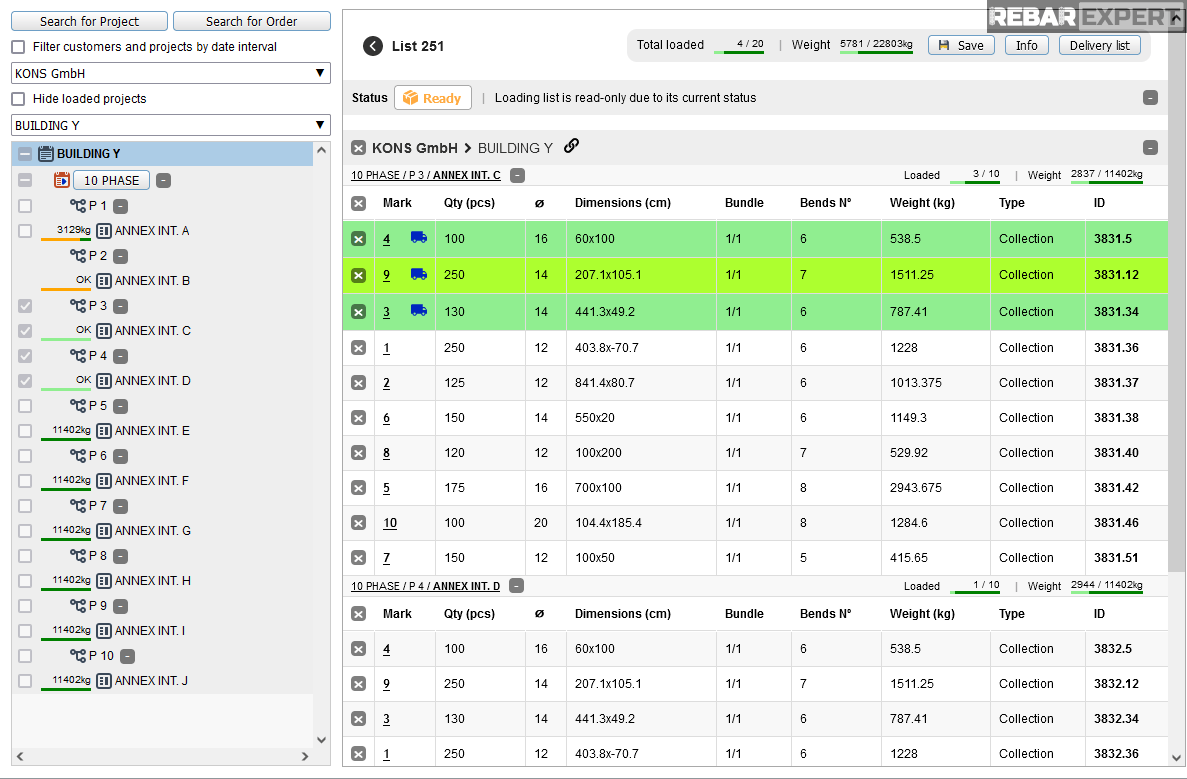

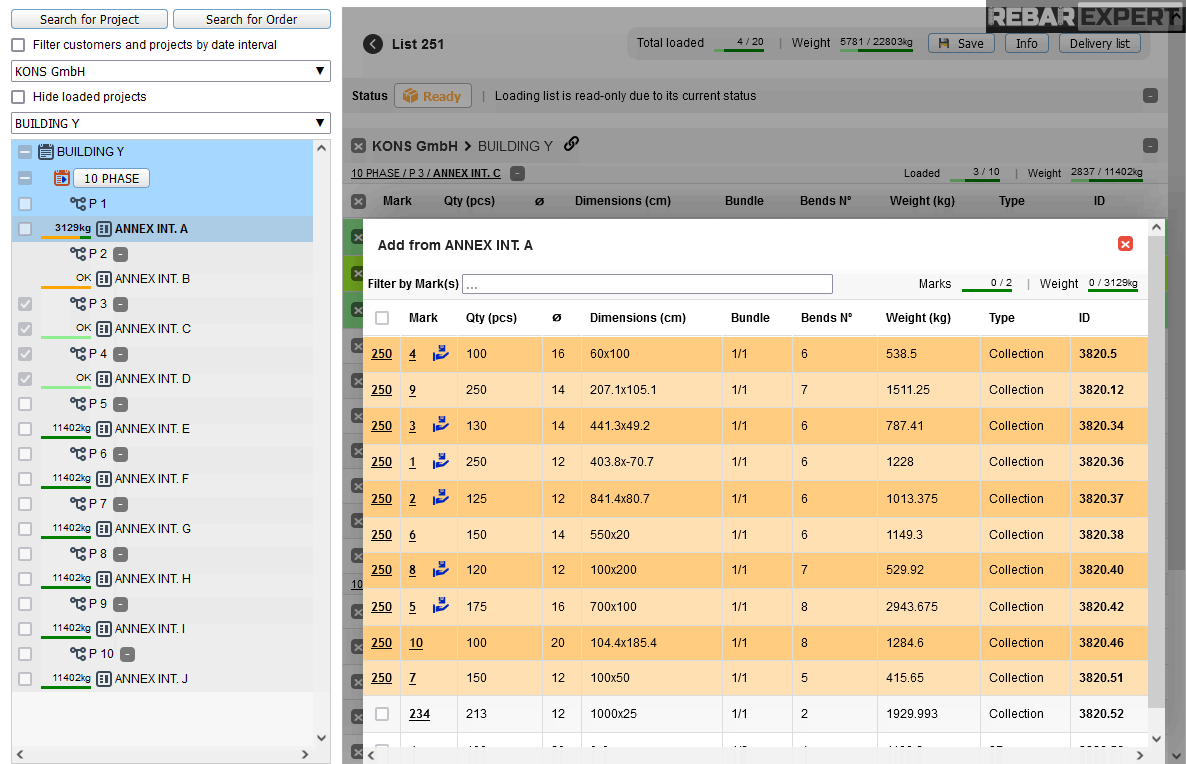

Creating loading lists using a user-friendly, feature-rich system.

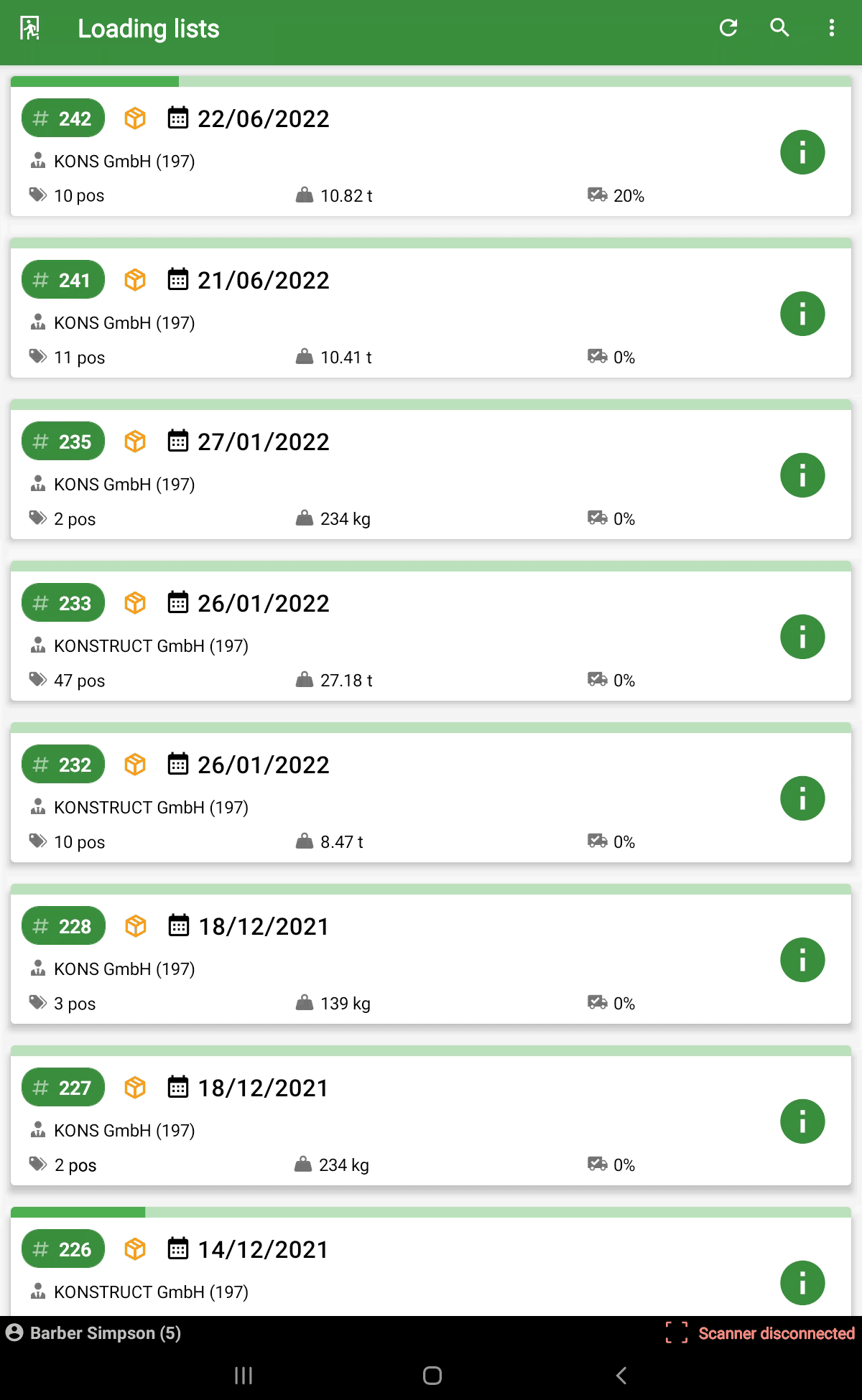

Loading and delivery validation using mobile technology and QR code scanning.

ESTIMATE LOSS

Calculate an estimated loss for your rebar shop

Insert the requested information and you will get an estimate on how much money RebarExpert can save you in a year.

This is a complex calculation which identifies the impact of implementing RebarExpert as a solution to increase production time.

Stop wasting production time and improve the following:

Steel lists and production tags generation.

Manual production reporting.

Validation, error handling and correction.

Cut-to-length optimization and simulation.

Stock resupply calculation.

Proper team communication.

FREQUENTLY ASKED QUESTIONS

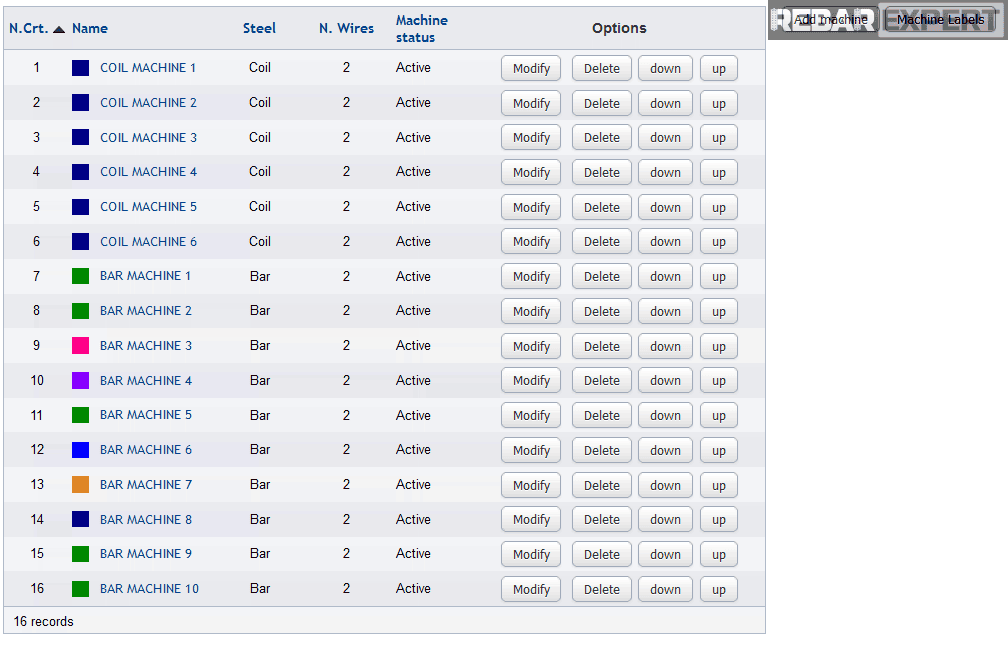

How to produce more with the same machines ?

Specialize coil machines to work with a maximum of 3 wire diameters.

Feed the machine from at least 5 coil holders and work with 2 wires, at all times.

Balance the workload by automatically assigning production to machines.

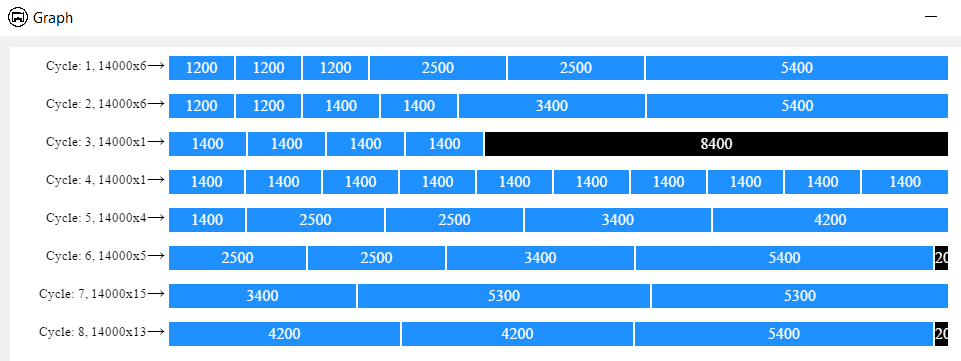

Run cut-to-length optimization simulations to identify the best stock lengths to order for minimizing waste.

Minimize the distance between the machines feeding racks and the storage place of wire rods.

Use at least 2 cranes on each production plant section: one for feeding operation + one for transport of finished products.

Minimize production down-times by replacing the hand-written tags and operator-written production reports with their digital counterparts.

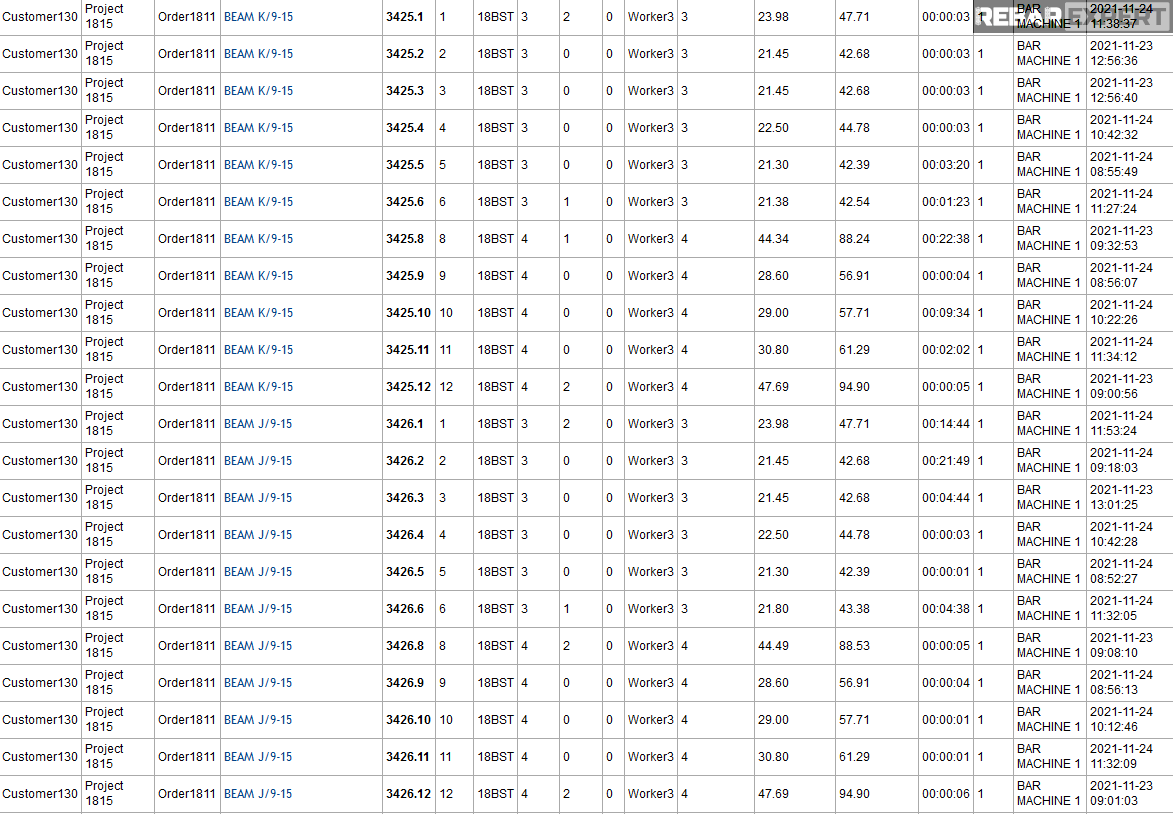

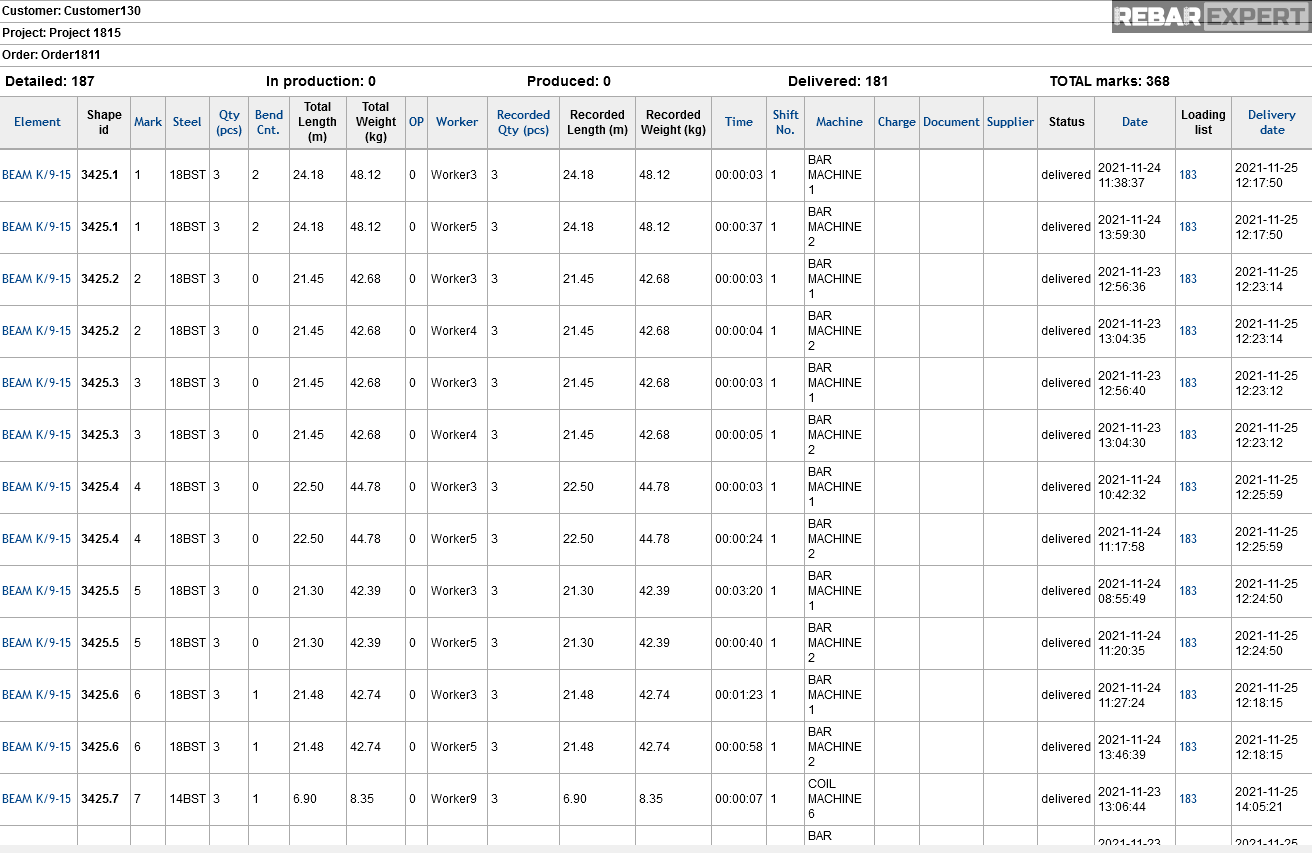

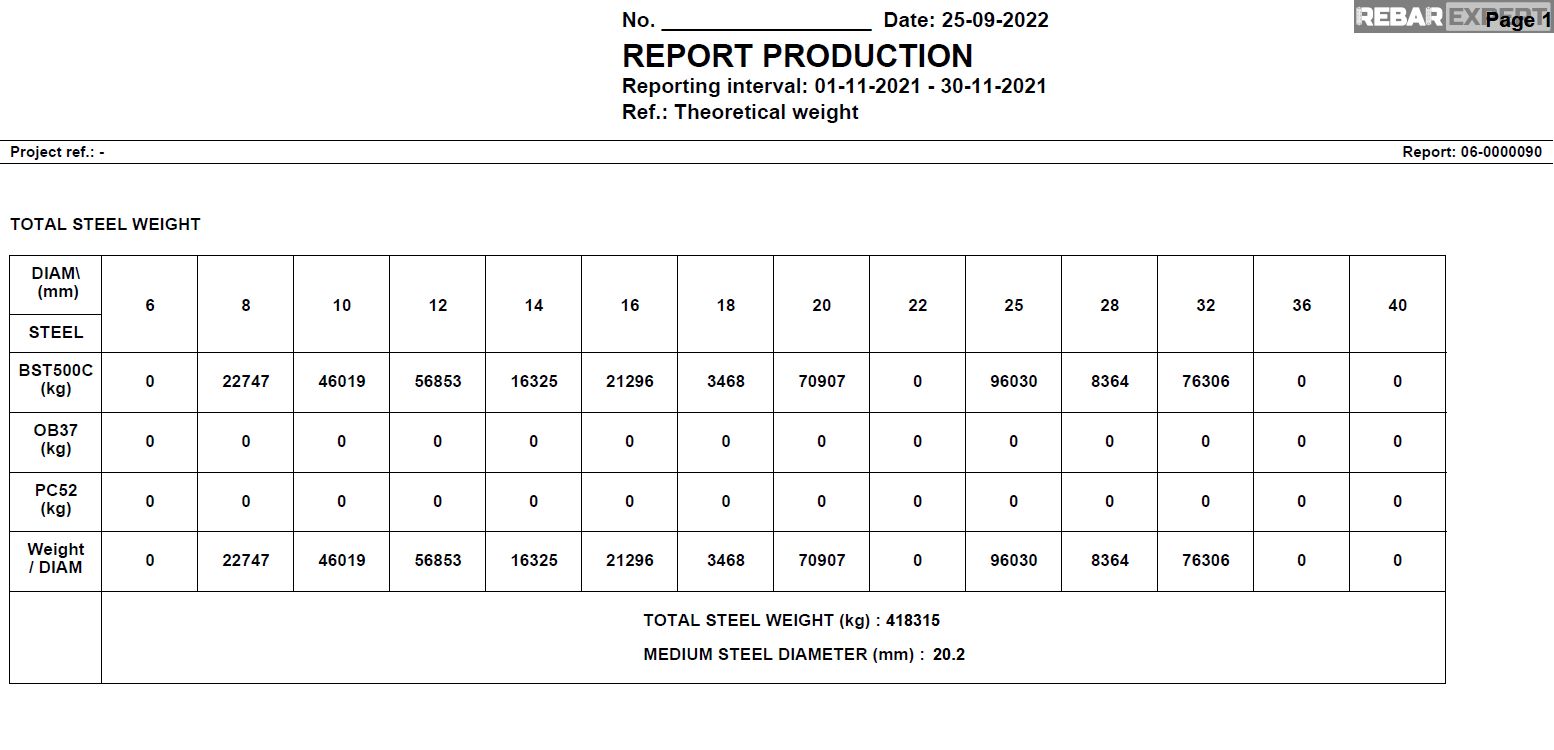

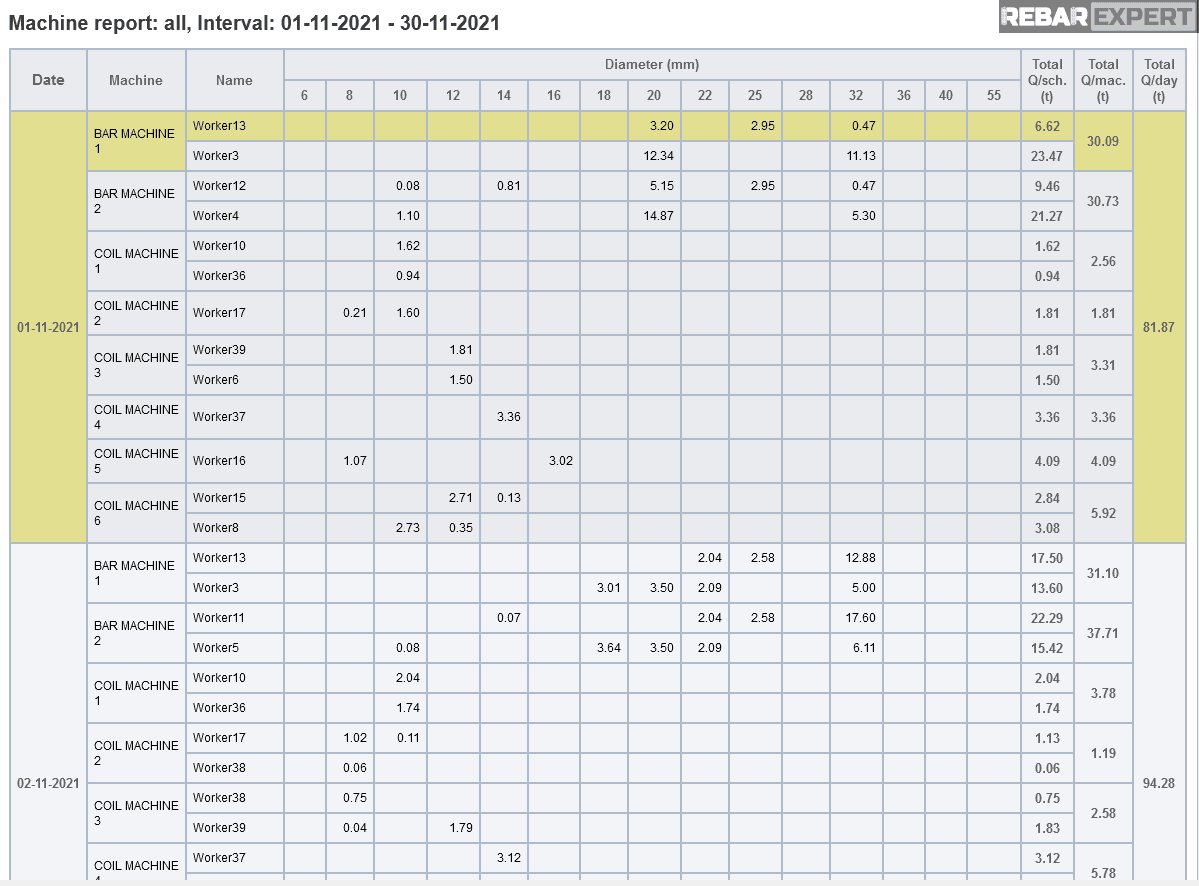

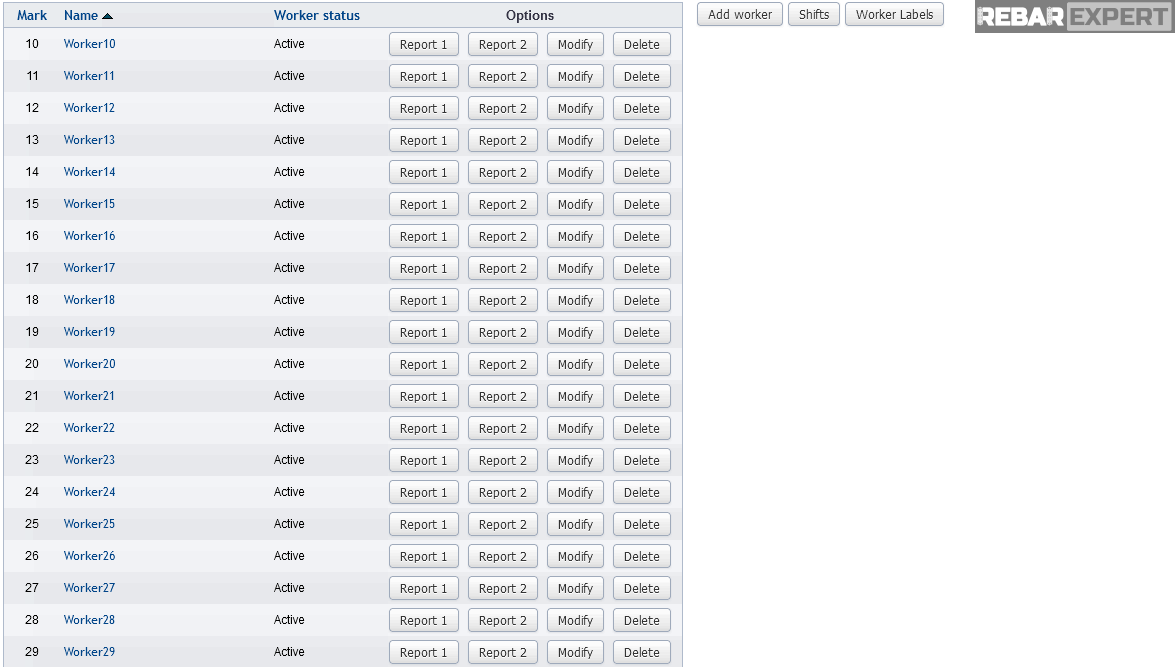

RebarExpert Real-Time Production Recording is a precision system, which works with printed customizable tags and centralizes all production information in complete production reports: production stages, operator activity (working shifts), machines performance, steel stocks, all based on steel qty. (diameter, bar / coil).

How do you label the products ?

Identify all rebar shape bundles using automatic software-generated tags.

RebarExpert generates tags for each position, using a tailored template (over 30 tag formats) containing BVBS-compliant barcodes that can be directly read by the machine using a barcode scanner.

How to keep my customers happy ?

Track finished products by priority and electronically supervise loading and delivery to prevent errors.

Ensure fast delivery times and provide proper documentation.

RebarExpert Real-Time Production Recording, Loading Lists and Delivery systems ensure the products are produced, tagged, loaded and delivered according to priority, using mobile technology to display warnings and avoid errors.

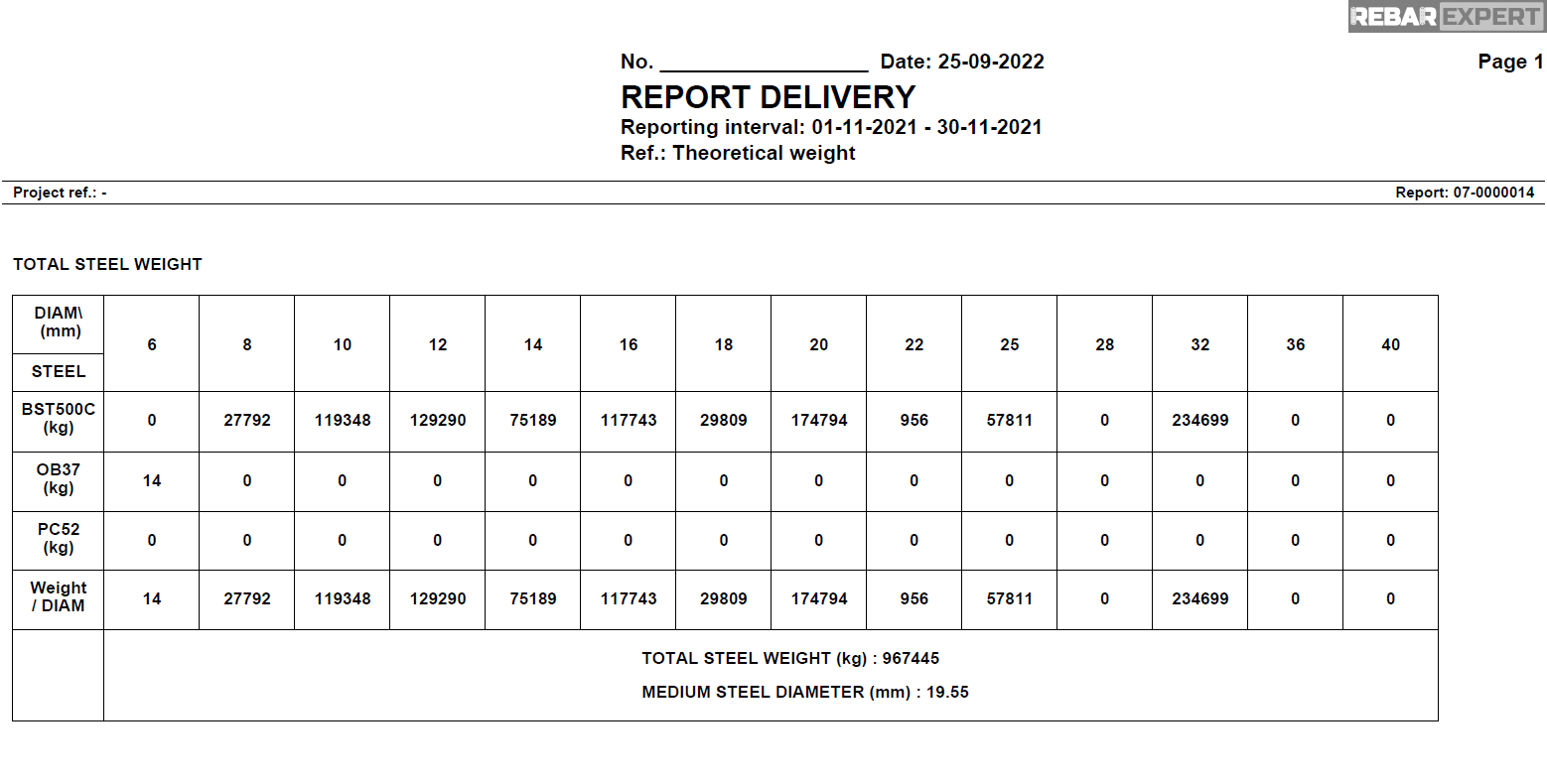

How do I know if my business is improving ?

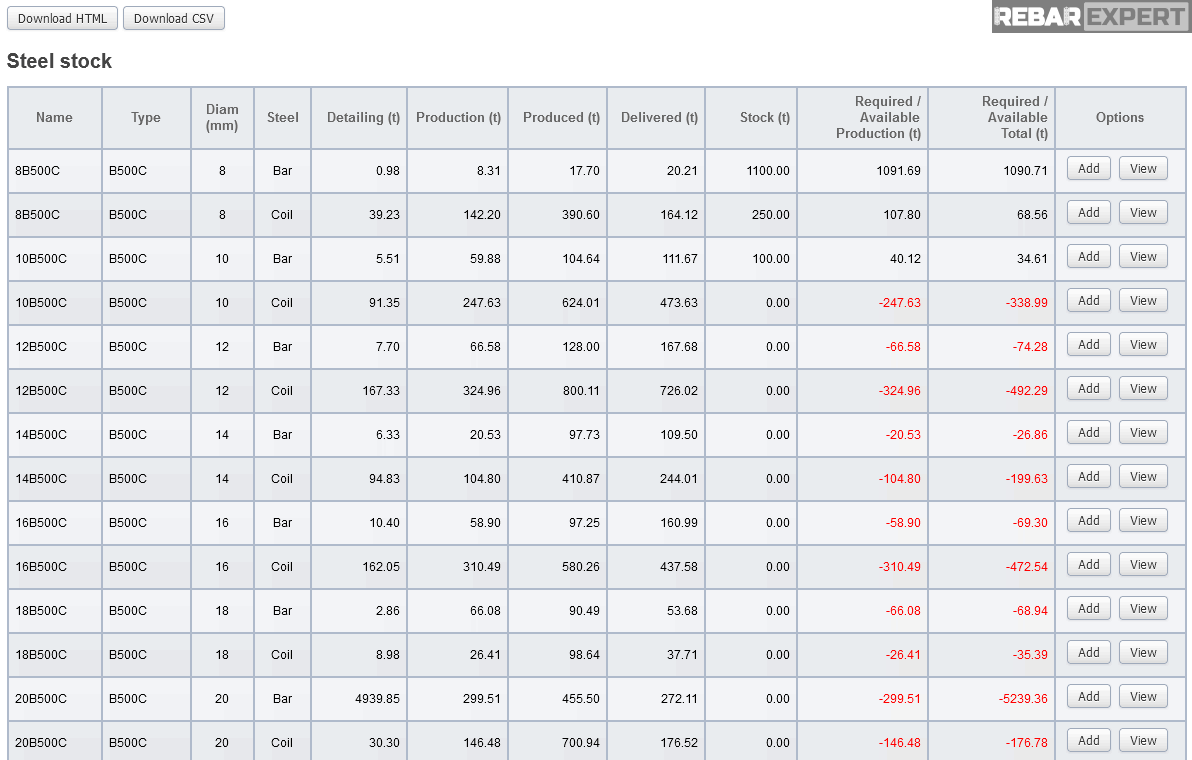

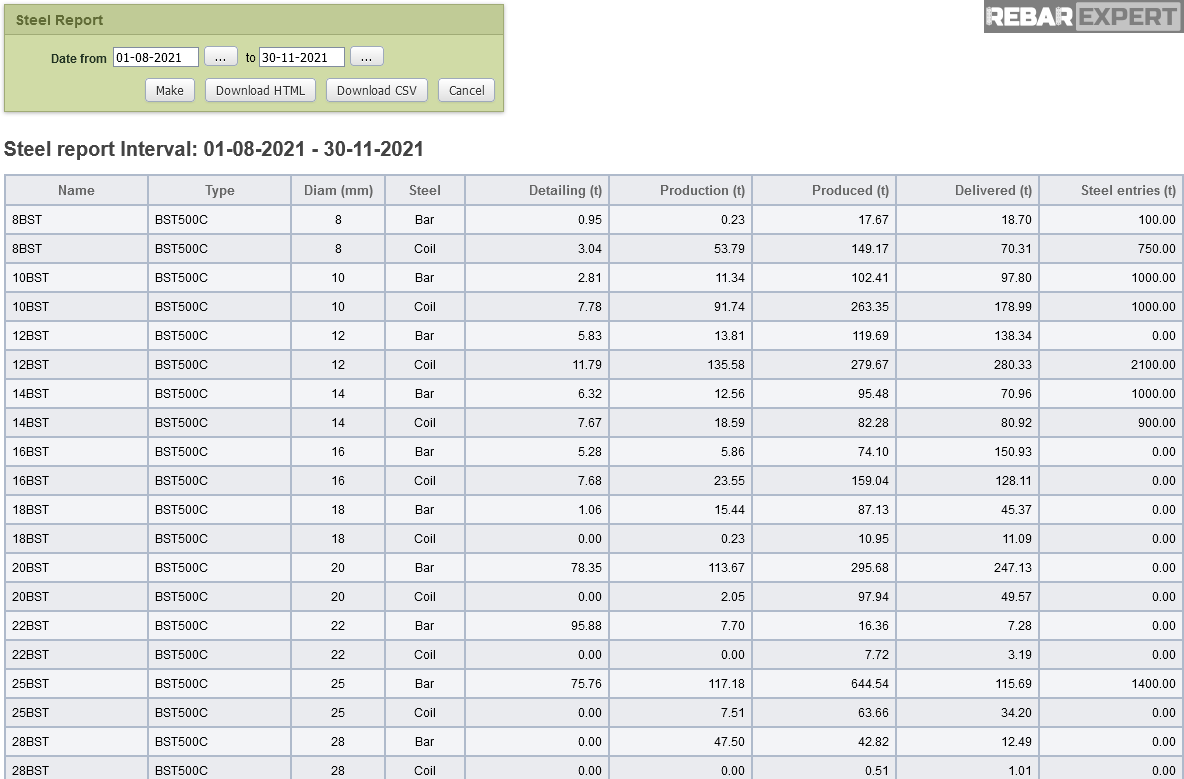

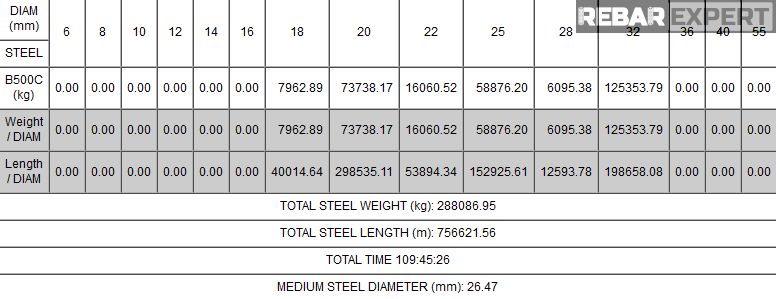

Keep track of the steel quantities: steel stock entries, detailed, in production, processed, in delivery, and delivered using specialized reports.

Keep track of the steel quantities the machines produce (per hour, per shift, per day, per month, per year)

RebarExpert has a wide range of reports to measure the rebar shop’s performance.

How to build customer loyalty ?

Work with established partners with solid business models which can bring value to your business through support, training and dedicated development.

The international team of experts behind RebarExpert has all the ingredients needed to help rebar shops thrive.

To name a few:

– Training

– Award-winning support team

– On-going development and updates

– Custom features on demand

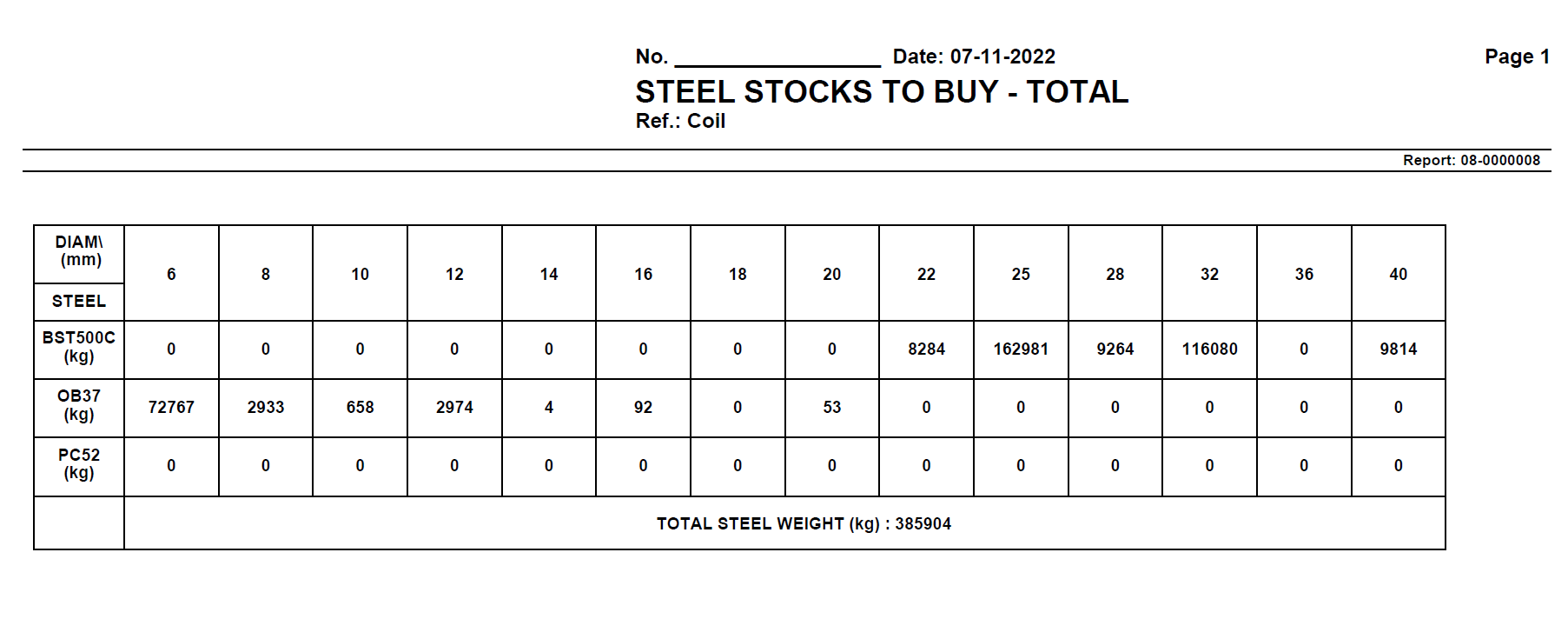

How much steel stock do I need to order ?

Order the right amount of steel stock based on order demand, priority, and cut-to-length optimization simulations.

RebarExpert continuously keeps track of the order demand, broken down by diameter (coil and bar), in the “Steel to Buy” report.

How to use steel as efficiently as possible ?

Use cut-to-length optimization and cut-to-length optimization simulations before ordering steel stock for future production.

RebarExpert offers best in class cut-to-length optimization algorithms and a graphical representation of the optimization report.

Cut-to-length optimization can be run on one or multiple clients, projects, orders and members.

What are the most time-consuming activities in a rebar shop ?

Crane travel time from the place where the steel stock is stored to the machines.

Crane travel time transporting the produced rebar shapes to the delivery area.

Manually introducing production data information in the machine console.

Manually written production reports about produced rebar shapes.

Feeding the machines with raw material.

RebarExpert saves production time by automatically tracking, recording, and delivering production using BVBS-compliant tags and QR codes.

How to avoid errors in the production flow ?

Document every phase of the project/order from detailing to delivery.

Keep the evidence of all rebar shape tags given in production to the machine operators.

Ensure availability of production reports broken down by operator and position.

Account for steel traceability.

Supervise loading and delivery of the finished products, while summarizing everything in a report for later reference.

RebarExpert is built to minimize the window of error and if an error still occurs it will provide warning messages with all the necessary information to fix the cause so they won’t happen again. To name a few:

– completeness of production information (from detailing to delivery)

– prevent the production of the same position twice

– prevent operator input error through barcode scanning

– make use of loading lists to correctly identify the positions for delivery

– full steel traceability

How is the software implemented ?

RebarExpert is split into modules that can be implemented step by step according to a flexible payment plan tailored to the customer.